We are a leading cathode hanger manufacturers. We provide the standard certified range of Cathode and anode hanger, which is manufactured by our team of deft experts using the quality raw material and modern technology following the international quality norms and guidelines.

Our manufactured products are developed under the strict supervision of our quality associates. To cope with the diverse requirements of the clients we offer these products in customized specifications.

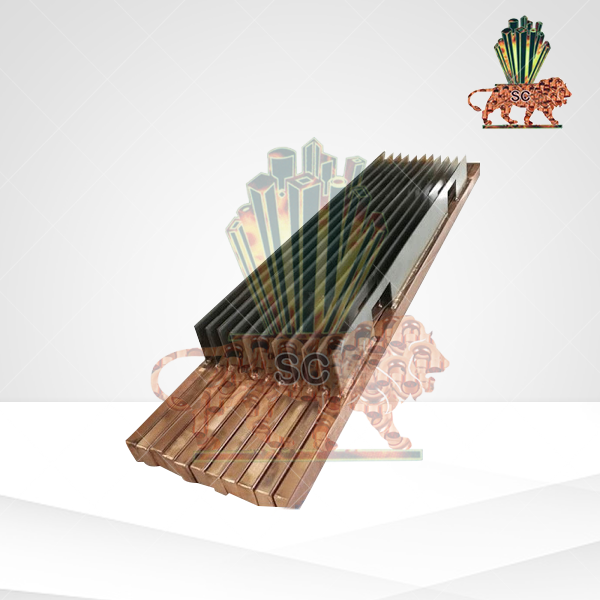

We use only verified quality stainless steel/titanium blades for each cathode manufactured. The cathode blades are welded to the hanger bars by robotic welding. We manufacture our cathode hanger bar from 316L Stainless Steel, Titanium, or Duplex Alloys.

Blades can either be welded directly to the bottom of the hanger bar or bent according to the client’s specifications.

Reputed Cathode And Anode Hanger Exporter

We offer them in customized designs according to the client’s requirements. Our hanger bars are manufactured from high conductivity, high strength copper material, and have a high-strength metallurgical bond between the copper hanger bar and the stainless steel encapsulation. The cathode sheets are welded to the hanger bars using a similar metal weld which decreases production time. We also supply our range for copper,cobalt, Nikel metal hydrometallurgy electrowinning and electrolystic deposition.

Due to the complex weld of copper to stainless steel or titanium, this process has been streamlined by welding stainless steel/titanium directly to stainless steel/titanium by utilizing cladded bar technology. The copper bars are now coated with stainless steel or titanium employing a mechanical extrusion bonding process. Through this technique, the copper and stainless steel/titanium become a unit and provides advantages like increased conductivity, better corrosion resistance, increased production due to simplicity of the weld, strengthens the hanger bar and Increases overall durability.

Being a renowned anode hanger manufacturers, we only manufacture anodes that are made using the rolling process. They are produced from high-quality rolled-lead blades from tin-lead- calcium alloy. This gives anodes an extended life expectancy which leads to higher productivity and lower operating costs. All the manufacturing steps are completed with the utmost precision, absolute quality consciousness, and the greatest technological literacy. The advantages are better density and particle structure. Another positive aspect is that contamination of the electrolysis baths is lower, and there are fewer impurities in the metal deposited on the cathodes. Our hanger bars of the anodes are manufactured according to specific customer requirements.

We also supply range of anode accessories for use in copper, nickel, cobalt and zinc electro-winning such as anode separators and anode bags.

Product Gallery

Electrolysis

Oil and Chemcial indurty

Hydro metallurgy

- Plating

- Electrolysis

- Hydrometallurgy

- Oil and Chemical industry

- Corrosion resistant Bus Bar

- Acid and alkali resistance

- Complete metallurgical bond

- Superior Conductivity

- Environmentally friendly

- Custom thickness available.High conductivity, high strength copper header/hanger bar

- Fully encapsulated antimonial lead casting around the header/hanger bar

- Superior quality lead welding of the anode blade to the header/hanger bar

- Fine-grain structure

- No cracks or voids

- Perfect flatness

• Manufactured from 316L Stainless Steel, Titanium or Duplex Alloys

• Provide Customized Designs to Suit Client Requirements.

• Robotically welded for consistency and strength

• Production time decreased due to similar metals

• Cold rolled 2B finish for ease of copper stripping

• Increased conductivity due to continuous welds

• Welds are more corrosive resistant

• Dimensional stability to the entire cathode

• Blades can either be welded directly to the bottom of the hanger bar or bent to the client’s specifications. Lifting brackets or lifting windows can also be manufactured into the design for ease of automated cathode handling.

A permanent stainless steel cathode plate is widely used in Sn/Cu/Ni electrowinning.

The plates use 316L stainless steel,2B surface handing.

Our stainless steel cathodes adopt special surface treatment.

“V” type groove at the bottom is designed contributing to an easy Cu peeling.

It has a long service life, at least 15 years.

The performance of the edge clip bar was stable which can decrease the cost.

Stainless steel cathode plates are featured with low maintenance and efficient capacity.

| Shape | Capabilities |

| Round Rod | Dia 6.35mm-Dia150mm |

| Square | 28mmX28mm |

| Rectangle | Max 100mm width |

| Wire | 0.76mm-6.35mm |

| Available Rod Length | Up to 12m |

| Typical Ti Thickness* | 0.76mm-2.54mm |

| Forming,Shaping,Welding | Custom forms and shapes available upon request |

| Additional Cladding Materials | Zirconium, Niobium ,Stainless ,Tantalum, Customer Specied Alloy |

| Additional Core Materials | Aluminum, Steel, Customer Specified Alloy |

- Explosion Rolling

Clad material: Stainless steel AISI-304 or 316L

Core material 2: carbon steel Q235

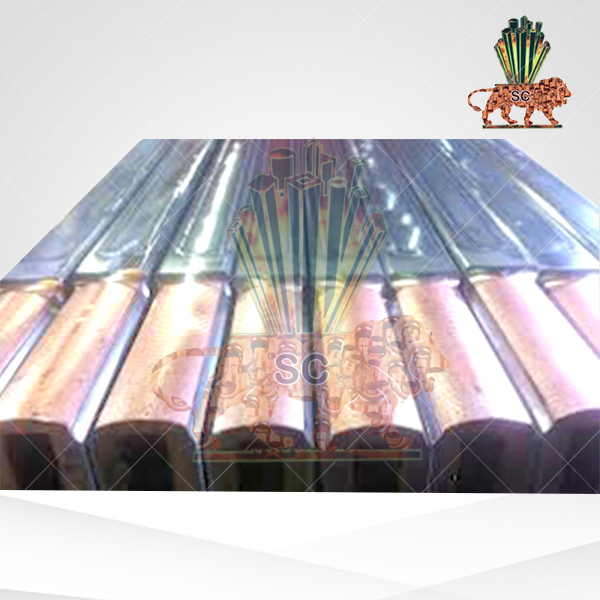

Thickness: stainless steel 2mm, copper 2.5mm and the center is carbon steel or built to order Cathode hanger bars can be divided into three types as follows, Cathode hanger bar made of copper and steel(from outside to inside) Cathode hanger bar made of stainless steel and copper (from outside to inside) Cathode hanger bar made of stainless steel 316L/304 and copper and carbon steel(from outside to inside)three layers.

Core material 1: Cu acc. to E-Cu58, CU-ETP, CW004A, UNS No.C 11000

Clad material: Stainless steel AISI-304 or 316L

Core material 1: Cu acc. to E-Cu58, CU-ETP, CW004A, UNS No.C 11000

Thickness: stainless steel 2mm, copper 2.5mm and the center is carbon steel or built to order. Over ten years experience, we found this manufacturing method for customers. With low price, this cathode hanger bars provide same strong corrosion resistance and best possible electrical conductivity.

Core material 2: carbon steel Q235