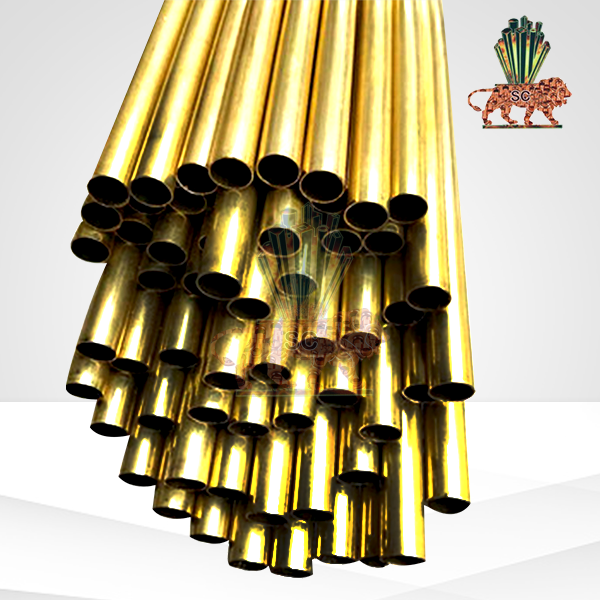

We, Shreya coppers are one of the supreme manufacturers of a wide range of brass tubes and pipes one of them is 70/30 brass tubes/pipes.

We excel in manufacturing and exporting our finest quality 70/30 Brass Tubes and pipes. Our company holds a leading market position due to its superior and more innovative products.Our offered brass pipes/tubes are manufactured by our skilled workforce, by using high-quality material and modern techniques in compliance with the specified quality standards.

Our manufactured 70/30 brass tubes/pipes are scrupulously reviewed and verified by our quality experts to ensure flawless and durable range. Our 70/30 brass tube is available in multiple sizes and specifications and they are also customized to meet the diverse requirements of the clients.

Owing to its superior heat conductivity, longevity, and maintenance, our brass tubes, and pipes are used in various industries.

Reputed 70/30 Brass Tubes/Pipes Suppliers

All our products are manufactured with high-quality raw materials and supplied to the customer with a complete guarantee. We offer our 70/30 Brass Tubes in a variety of specifications and grades to satisfy the varied customer needs. We produce our brass tubes and pipes with a wide range of length, diameter, size, hardness, and alloys.

We can also produce the Brass tubes in various shapes as per the customer’s requirements like hexagon, square, rectangle, and round shapes.The standard 70/30 brass composition is 70% Cu and 30% Zn having a small quantity of arsenic to prevent denitrification.

The brass may be turned into soft and hard brasses, by changing the amount of zinc and copper in it. These brass tubes are used for sugar industries, hand pumps, etc. and are also known as “Sugar Brass Tubes”.

This alloy is an optimum combination of strength and ductility and is often chosen when there are extreme cold working properties and when relatively low cost is looked-for.

Product Gallery

Sugar Industry

Defence

Power House

- Hand Pumps

- Ammunition

- General Engineering

Our brass tubes are tested and are under stringent examination at each stage of manufacturing cycle from raw material obtained to the product dispatched. All the raw materials used in the manufacturing of brass tubes are properly tested to ensure conformity with international standards and consumer specifications.

- Sturdiness

- Corrosion resistance

- Durability

- Drift test

- Flattening test

- Mercurous nitrate test

- Hydraulic test as per specification.

| ALLOY |

STD APPLIED |

ALLOY DENOTATION |

SYMBOL |

CU |

PB |

FE |

ZN |

P |

AL |

SN |

AS

|

TOTAL IMPURITIES |

| Sc Brass 70/30 |

BS | 2871 PART3 | CZ – 126 | 69.0-71.0 | 0.07 |

0.06 |

REMAIN | – | – | – | 0.02-0.06 |

0.3 |

| ASTM | B-135 |

C 26000 |

68.5-71.5 |

0.07 |

0.05 |

REMAIN | – | – | – | – | – | |

| DIN | 17671 |

CuZn 30-2.0265 |

69.0-71.0 |

0.05 |

0.05 |

REMAIN | – | – | 0.05 |

– | 0.1 | |

| NFA | 51-102 |

CuZn30 |

68.5-71.5 |

0.07 |

0.06 |

REMAIN | – | – | – | – | 0.3 | |

| JIS | H- 3300 |

C2600 |

68.5-71.5 |

0.07 | 0.05 |

REMAIN | – | – | – | – | – | |

| IS | 1545 |

CuZn 30 AS |

69.0-71.0 | 0.07 | 0.06 |

REMAIN | – | – | – | 0.02-0.06 | 0.3 |

| ALLOY | STD APPLIED |

SYMBOL | CONDITION | YIELD, STRENGTH N/mm2 |

TENSILE N/mm2 |

ELONGATION % |

HARDNESS HV 5 |

GRAIN SIZE Mm (75X) |

| Sc Brass 70/30 |

BS |

CZ – 126 |

M, TA, O |

– | – | – | 150MIN, 80-105 , 75 MAX. |

0.05 MAX |

| ASTM |

C 2600 |

H 58, H 80 | – | 370MIN, 455MIN. |

– | – | – | |

| DIN |

CuZn 30-2.0265 |

F28, F35, F42. |

180MAX,200MAX, 320MAX. |

280-350,350-420, 420MIN. |

– | – | – | |

| NFA | – | – | – | – | – | 80-105 | 0.010-0.45 | |

| JIS |

C2600 | O, 0H, 1/2H, H |

– | 275MIN,275MIN, 373MIN,451MIN. |

45MIN, 45MIN ,20MIN. | – | 025-.060,035MIN | |

| IS |

CuZn 30 AS | O, TA, HD |

– | 375MAX,340MIN, 385MIN | 55 MIN | 80MAX, 80-105 , 130MIN. |

– |